February 9, 2022 in ARTICLES

Running out of stock? Hoarding is not a solution.

Investing time and money in making products available is more important today than ever before.

The relentless waves of COVID-19 and the surge of the Omicron variants in every state apart from Western Australia have crippled the labour market and created rippling effects across the supply chains. Capacity constraints and delivery agents have been completely upended. Product availability is at risk. These challenges are not going away.

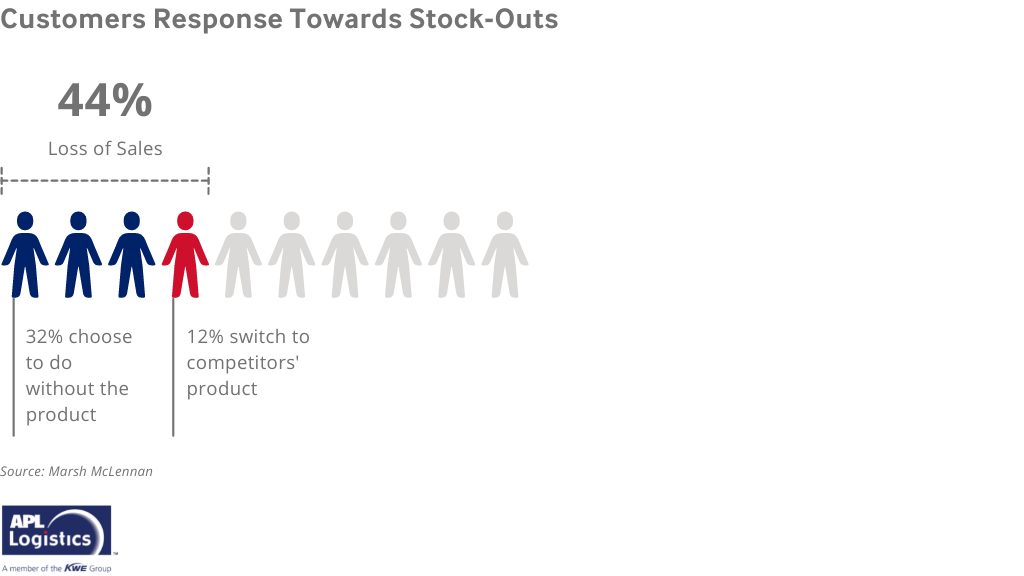

With the rising digital trends, there is a greater need for speed and efficiency. Today, customers no longer tolerate out-of-stock items and long waiting times for restocking. A recent study by Marsh McLennan has revealed that 32% of the customers are willing to forsake an out-of-stock product, and 12% will purchase a similar product from the competitors.

As e-commerce competition heightens, the fight to retain top of mind in customers will intensify. Retailers raced to increase or “hoard” orders in fear of stock-outs triggered by the lack of raw materials globally and limited production capacity. Consequently, retailers absorb the increasing costs to get the products on shelves. However, this is not sustainable.

Stock-outs are not new for the retailers. On average, retailers expect to record a 5% loss of sales annually due to out of stock items. The impact of these ‘out-of-stocks’ runs deep.

Organizations that address the customer demands and consistently make products available stand to gain market share and dominance. Organizations can strategize and manage their stocks smarter through logistics innovations and investment in three key areas:

Harness logistics innovations to plan and forecast demand

Over the past two years, consumer behaviour and spending habits have changed significantly, making it impossible for organizations to manage demand planning and forecasting functions through traditional ways. Organizations rethinking their business strategies are moving to the next phase of pandemic planning, transitioning from recovery to identifying the emerging trends.

The pandemic exposed the brittleness of lean supply chain inventory management such as “Just-In-Time”. There is an emerging trend towards adopting the “Just-In-Case” approach and keeping more stocks on hand. The question remains, how does one plan and forecast the right safety stock levels to protect them from the supply-chain fluctuations?

1. IMAGINE WHAT’S POSSIBLE WITHOUT REAL-TIME COMMITMENT

Organizations can harness logistics innovations such as the Digital Twin to address their business needs accurately, simulating disruptions and managing risks. Essentially, digital twin provides a virtual copy of your actual supply chain environment so that you can plan for contingencies across the “what-if” scenarios. Through advanced analytics and artificial intelligence, the digital twin ensures that all the complexity that drives suppliers, factories, manufacturers, distribution facilities, transportation, customer needs and associated costs and risks are met. This technology also allows organizations to optimize their supply chain inventory management, imagine what is possible and help the team come to a decision quickly without having to experience the real thing.

2. PLAN BETTER WITH DATA

Besides managing risks, organizations can rely on Data Analytics to gain valuable insights, market trends, drive inventory scenario modelling and better decisions. Digital technology, such as data mining and analysis techniques, effectively drives visibility across an organization’s supply chain ecosystem. Data such as the supplier data, PO, ERP, finance, shipping and milestone data, inventory data, POS, customer data, IoT, are commonly used to provide more visibility, leading to a connected supply chain.

With the right technology tools, organizations can better stock up on popular products ahead of demand predict demands or potential risks ahead of time.

rethink your inventory strategy

Today, as we revolve our world around our customers, changing spending habits plays a huge part in defining an organization’s inventory strategies. Cashed up customers are buying home improvements products, housewares, health and wellness, fitness and lifestyle products and hi-tech equipment at an unprecedented rate. To meet customers’ demands with agility and speed, organizations should constantly examine their supply chain inventory management strategies and how well they match customer demands to succeed.

Here are five key approaches to think about:

- Adopt a multi-sourcing approach. Procurement leaders are moving away from single product providers and diversifying suppliers in different regions, such as Vietnam and Indonesia, for apparel and footwear. Localizing the supply sources closer to demand could also reduce exposure to delivery delays and bottlenecks.

- Augment inventory and expand the pockets of inventory within the supply chain while considering the products on priority, costs, optimum inventory locations and centralized pick locations.

- Overstocking could lead to unnecessary costs. Organizations should weigh the priorities of their goods and rethink their pricing strategy to move the products.

- Changing fulfilment models to support the e-commerce hub-and-spoke model. Online sales are driving greater demand for urban fulfilment centres with heavy investment in automation to drive efficiencies, speed and lower cost.

- Modernize your supply chain environment with technologically driven partners early to stay ahead of the curve.

keep your supply chain resilient and sustainable

Finally, organizations need to ensure their supply chain is rooted in resiliency with the right logistics innovations and a good inventory strategy. Being agile and operationally flexible in executing changes within the supply chain is essential in meeting any crisis. A well-equipped, empowered team capable of making the right decisions is a game-changer in managing multi-layer supply chain challenges.

In addition to having a well-equipped team, organizations should emphasize upskilling their current labour force to modernize their supply chain, fast-track technology and automation capabilities with the right talents.

Besides having the right blend of people and technology, organizations must work towards a sustainable supply chain. Product availability is not only affected by the pandemic, extreme weather events, changing geopolitical conditions, and access to raw materials are posing bigger risks than before.

The benefits of being resilient are the credibility and loyalty gained in meeting the changeable demands of the customers. Similarly, organizations lacking sustainability are at risk of getting their products penalized by regulators or unloved by customers. It is never too late for organizations to go green and embark on sustainable practices.

The conventional one-size-fits-all method will no longer be sufficient to succeed in today’s world. Organizations need to invest in technology and people, constantly rethink their inventory strategies and adopt sustainable practices to meet the changing customers’ expectations.

Author: Mark Haslam, Director of General Management, Australia & New Zealand

FOLLOW MARK ON LINKEDIN