May 20, 2024 in ARTICLES

Order Planning: Managing Your Supply Chain in the Age of Disruption

In the fast-paced world of global trade, the Suez Canal stands as a critical artery, facilitating nearly 30% of the world’s global container trade. When disruptions strike, the repercussions reverberate worldwide. Global supply chains are, however, exposed to many other disruptions caused by geopolitical tensions, strikes, severe weather conditions, and- importantly- many other types of local and regional disruptions that do not make news headlines. These circumstances underscore the urgent need for resilient supply chains that can weather any storm.

Today, many companies attempt to mitigate the impact of supply chain disruptions through real-time visibility of goods in transit. However, real-time visibility alone may not be enough to build a strong and efficient supply chain, especially considering the continuously increasing risk of disruptions within global supply chains. Therefore, it is crucial to intensify focus on order planning and address the root cause of inefficiencies before they become issues.

The Power of Order Planning

In a recent panel discussion, leaders from across the industry converged to tackle this challenge head-on. At the forefront of their conversation: building resilient supply chains through order planning—a strategic approach that holds the key to anticipating, rather than reacting to, inevitable supply chain disruptions.

Jens Larsen, Head of Global Order Management at APL Logistics, led the charge, emphasizing the power of foresight in navigating today’s complex supply chain landscape. “The era of relying solely on in-transit visibility is behind us,” Larsen declared. “For companies to be successful in this environment, they must adopt a proactive, systemized approach to order planning.”

Traditionally, logistics operations have been reactive, with visibility limited to tracking orders and shipments in transit from the point of manufacturing to the point of consumption. Larsen pointed out, “This reactive approach only exacerbates issues downstream. By shifting the focus to order planning, organizations can address inefficiencies at their source, ensuring smoother operations and mitigating risks before they escalate.”

Forecasting for Resilience

The key to navigating supply chain disruptions lies in order planning, forecasting, scenario simulation, and the ability to connect demand and supply. Larsen stressed the importance of synchronizing supply with demand, noting that “Many companies still operate on outdated push-driven models. By embracing a more agile, demand-driven approach, companies can not only improve their revenue and enhance efficiency but also reduce costs and environmental impact.”

One of the most important aspects of driving these solutions is collaboration and ensuring that planning and continuous assessment of order flows become an enterprise-wide activity. Larsen emphasized the need for “breaking down silos within companies, fostering collaboration across teams and departments-from demand planning and sales to merchandising, buying, quality management, logistics operations, and sustainability. By working actively with the planning and status of orders, sharing demand and supply related information and insights across departments, organizations can streamline processes and make better financial decisions of how to execute the flow of products.”

Embracing the Future of Logistics: Expect the Unexpected

Looking ahead, strategic order planning, forecasting, and scenario modeling will play an increasingly crucial role in the future of logistics. By embracing order planning principles, companies can build resilient supply chains capable of thriving in an ever-evolving global marketplace where disruptions are imminent.

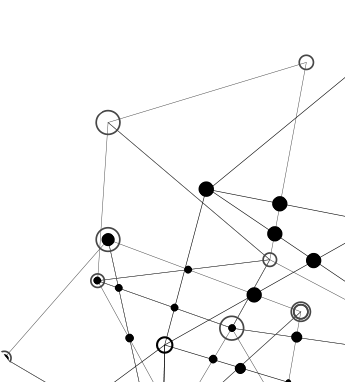

APL Logistics offers tailored order management solutions designed to maximize our customers’ revenues and profitability and optimize their efficiency and adaptability. Our Order Pilot solution combines advanced machine learning technology with industry-leading expertise to provide advanced order planning and control. Through predictive analytics and scenario planning, businesses can drive responsiveness, manage supply and demand fluctuations, identify potential bottlenecks, and proactively adjust their planning to mitigate risks—before executing.

About APL Logistics

With its global expertise and network spanning over 120 service locations across 60 countries, APL Logistics is committed to empowering supply chains for success. Whether navigating geopolitical uncertainties, natural disasters, or shifts in consumer behavior, our award-winning order management solution, Panom, equips businesses with the tools, information, and supply chain expertise they need to navigate complexity and drive sustainable growth.

Discover PANOM | APL Logistics’ Award-Winning Solutions