Synopsis

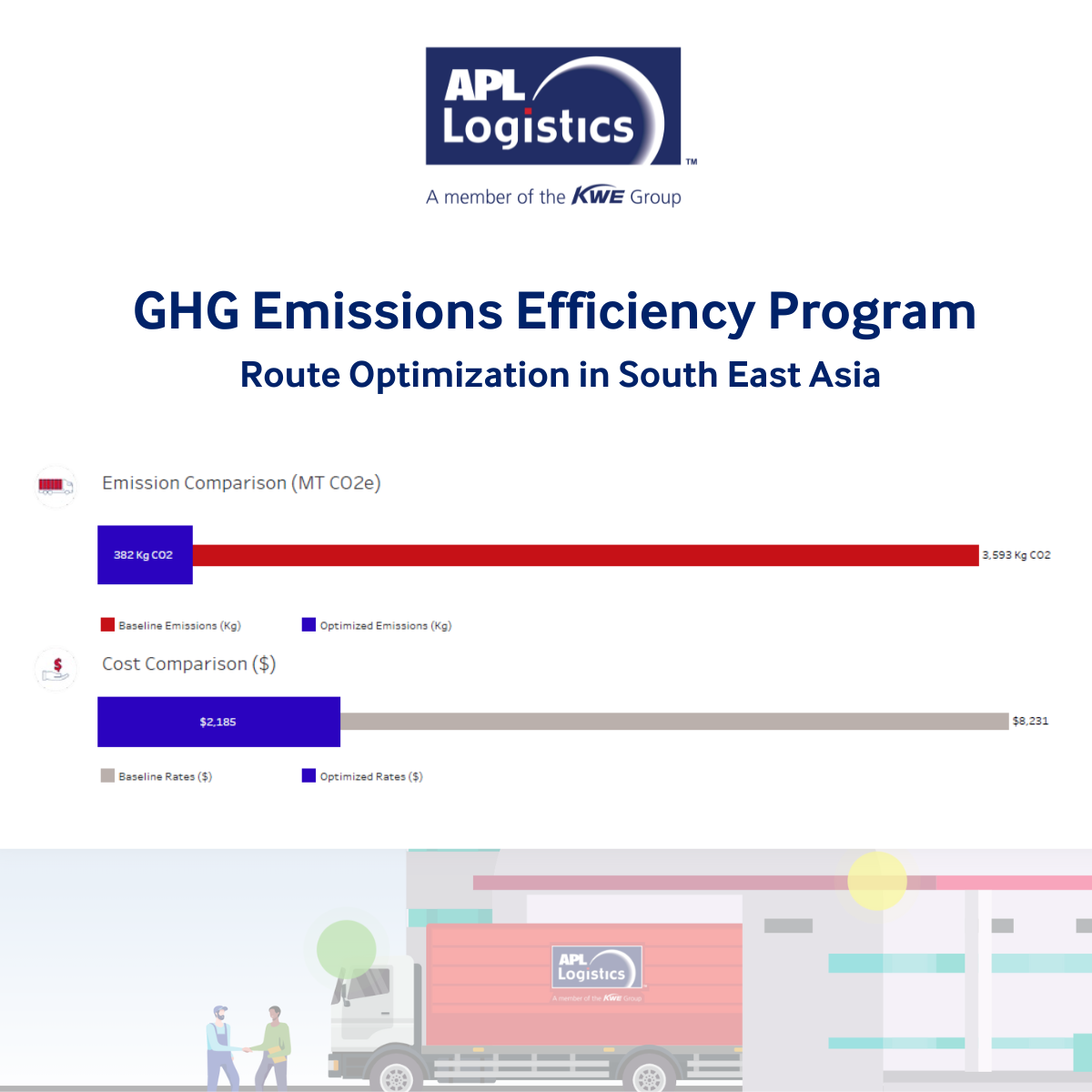

APL Logistics ran the Greenhouse Gas (GHG) Emissions Efficiency Program for a series of operations in Vietnam and Indonesia of a leading global sports equipment company and retailer of athletic shoes and apparel. Our origins operations and data team tracked the emissions for the trucking routes that resulted in an 89% reduction of GHG emissions and cost savings by 73% in Vietnam!

The objective of this program was to determine the most cost and emission-efficient routing during the shipment planning process, run simulations to evaluate the impact of the new routing option and plan for implementation at the origin, and ultimately perform these optimizations without impacting the final destination delivery.

Customer Overview

- A top global retailer of athletic shoes and apparel and long-time APLL partner and customer.

- More than 1,000 retail stores worldwide (including ecommerce), and thousands of retail accounts, independent distributors, and licensees.

Objective

- Determining greener and more cost-efficient routes for the customer during shipment planning.

- Performing these optimizations without impacting shipment final destination delivery.

APL Logistics Solutions

APLL’s Decarbonization Suite – Our premier collection of GHG measurement and reduction tools curated to help your company increase their supply chain emissions visibility, transparency, and reportability. The possibilities are endless:

- Aggregate and download reportable emissions data across all modes of transport

- Visualize overarching and carrier/lane-level emissions trends in your inbound logistics

- Calculate the emission and cost savings associated with route or mode optimization strategies

- Quantify the environmental impact of increased operational efficiency (container utilization, multi-modal transport, etc)

- Create internal and external showcases to disseminate these sustainability achievements

- Provide neutral and unbiased recommendations for managing Scope 3, Category 4 emissions

Benefits & Results

- As a result of this program, the customer was able to reduce their GHG emissions by 89% and 90% in each Vietnamese and Indonesian scenario, respectively.

- Similarly, the customer saw their costs drop by 73% and 52% with APL Logistics’ route optimization recommendations (streamlined transportation processes from factories to CFS or port).

- Fewer truck miles traveled improved traffic congestion, productivity, and safety in each transportation leg.

- Increased alignment with customer’s sustainability targets.

Challenges

- Underutilized truck loads sent from factories to CFS consolidation point.

- Missing factory KPI for on time delivery due to long distance travelled.

- Overnight driving and waiting for drivers due to distance between factory and CFS .

- Long and costly transit routes between factory and CFS/port locations in Vietnam and Indonesia.